Lignocellulosics track

The Lignocellulosic team supports the valorization of lignocellulosic biomass through the study of pretreatment processes and the development of biobased materials (wood, fibers, composites). The concept of digital twin, which structures the whole Chair of Biotechnology, is here declined according to two fields of intervention thanks to a multi-scale and multiphysics approach:

- The in-silico prediction of properties from the 3D morphology of heterogeneous materials,

- The modeling of transformation processes by adapted macroscopic formulations and numerical resolution tools.

The common approach to these two areas is to study materials at the microscopic scale (3D morphology at high resolution, observation under thermal, hydric or mechanical stress, measurement and characterization with classical or original devices developed in the laboratory). This allows us to feed and validate our predictive models in order to optimize the processes or the behavior of materials at the macroscopic scale. To limit the intermediate steps, the scale-up is based on a coupling between instrumentation/experimentation and modeling/high performance computing. The team is a reference for the relations between biobased materials and water (equilibrium, dynamics of coupled transfers, double scale effect ...).

For this purpose, the team has multidisciplinary skills including materials science (physical chemistry, mechanics, morphology), transfer science (coupled heat and mass transfers, fluid mechanics, mechanics of heterogeneous media), applied mathematics (meshing of real morphologies, resolution of large non-linear systems, numerical simulation), as well as the design of original experimental devices.

The applications studied are varied and are oriented towards different markets such as construction, transportation, packaging, energy, and biorefinery.

Developed Approaches

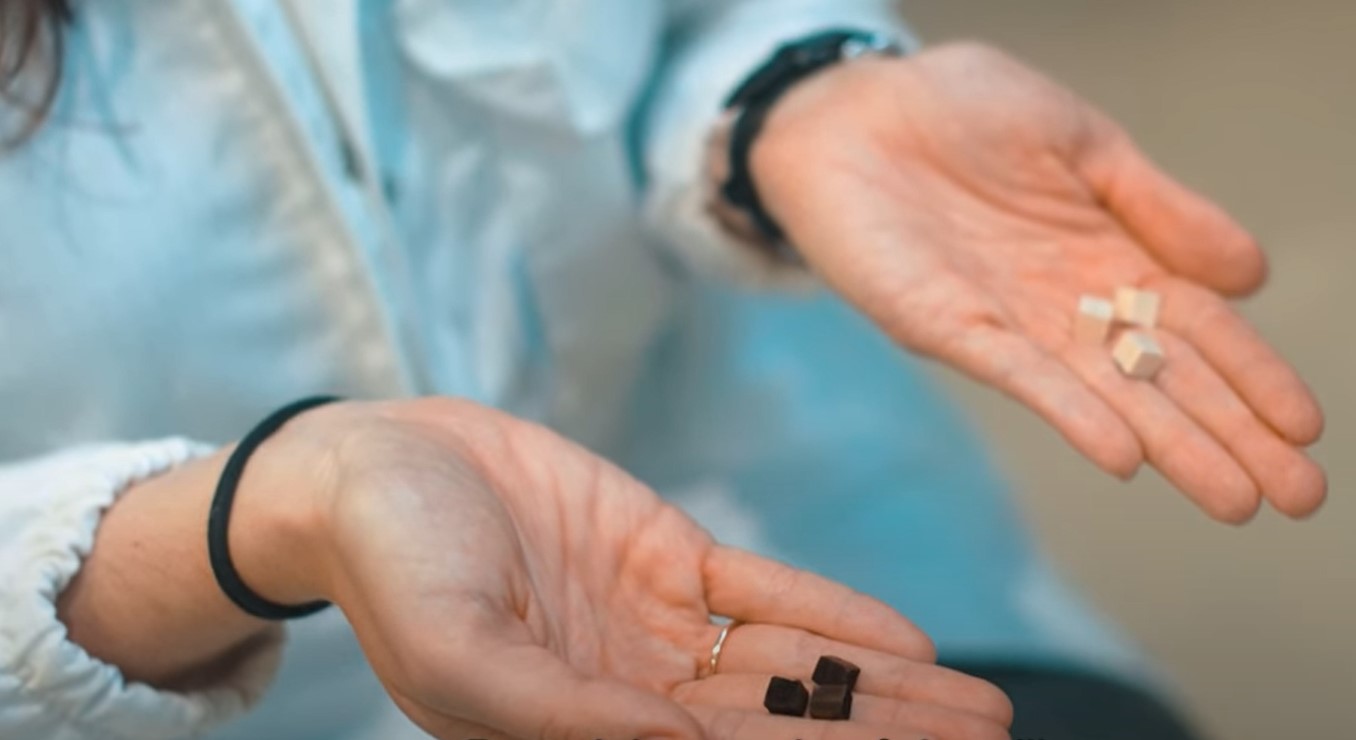

Study of biomass pretreatment processes

The pretreatment processes of biomass allow to improve its later use via morphological, physicochemical and properties modifications. Thus, different pretreatments and their impacts on biomass are studied: grinding, acid cooking, steam explosion, torrefaction, pyrolysis, thanks to original experimental devices and the imaging platform. The understanding and the modeling of the modifications during the treatment make it possible to anticipate the impact of the processes and to optimize their control with optimal conditions according to the biomass.

The modeling is based on a DAEM (Distributed Activation Energy Modeling) approach to predict the alteration of biomass properties from any operating conditions (temperature versus time). The modeling of coupled heat and mass transfers in porous media allows to study the effect of sudden changes of boundary conditions: for example, very fast heating phase at the beginning of acid cooking and steam explosion.

Design of composites with optimized properties

The study of structure-property relationships is developed from 2D/3D morphological observations, dynamic in situ observations under stress, and various characterizations of properties (hydric, thermal, mechanical), allowing the development of predictive models of the properties of biobased composite materials from real morphology. Our remarkable equipment in high resolution imaging allows us to take into account the local morphological heterogeneity of biomasses and materials (fiber orientation, fiber-resin arrangement...), thus refining the predictive multi-scale modeling and anticipating accurately the behavior of materials.

The team wishes to rely on the development of virtual morphologies and machine learning methods from the databases of materials already studied, to innovate in the design of materials with optimized properties by reverse engineering approaches.

Characterization of coupled transfers

To feed and validate all our predictive simulation tools, the team has developed a unique expertise in characterization at different scales. This allows us to offer a very complete range of characterization of solid materials, which can be divided into three categories:

- Thermal: conductivity, mass heat, stability,

- Mass: sorption isotherms, diffusivity of water vapor or other gases, imbibition monitoring by 2D and 3D X-ray imaging,

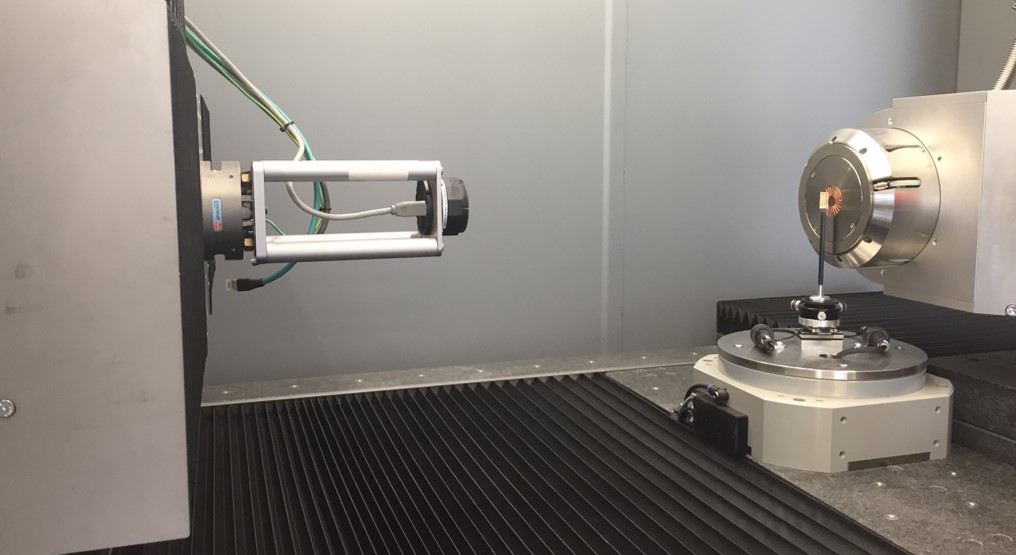

- Mechanical: mechanical testing machine positioned in our X-ray tomograph

The extraction of properties from experimental measurements is generally done with the help of simulation codes that allow to consider, at the experimental level, the coupling between properties (multiphysics) and/or the coupling between scales. This allows us to detect and quantify the effects due to local non-equilibrium between phases, very frequent in coupled transfers.

Examples of achievements

- Multiscale characterization of water and heat transfer within biobased insulators

- Study of the physico-mechanical behavior of oak barrels during wine maturation

- Fine instrumentation of samples for the study of drying and torrefaction processes

- Prediction of macroscopic properties by change of scale and taking into account the real morphology of the heterogeneous medium - 3D Biomat project

- Study of lignocellulosic biomass pretreatment by steam explosion: measurements on new prototypes and predictive modeling, by DAEM modeling, of the acid cooking and the explosive phase

- Direct numerical simulation of heat and mass transfer in porous media on 3D morphologies obtained by nanotomography - PredicTBiomat project

- Development of tools and models in the context of energy renovation - Smart-Réno project

Facilities

Characterization of materials

- Nano X-ray tomograph (EasyTom XL 150-160, RX Solutions), very versatile equipped with two sources (micro and nano) and two imagers (wide field flat panel and CCD sensor for high resolution). It allows to scan configurations ranging from 80 kg and 20 cm diameter samples to very small samples allowing a resolution up to 400 nm.

- Mechanical solicitation, water conditioning and imbibition devices adapted to the nano-tomograph.

- Confocal Raman microscope, for 2D topochemistry imaging (Alpha 300R, WITec)

- ATG-DSC, simultaneous thermogravimetry and differential calorimetry (Setaram TG-DSC SENSYS evo)

- High speed and high resolution surface characterization analyzer (BET)

- Climate chambers controlled in relative humidity and temperature

- Microtome

- Isothermal calorimetric titration (Setaram C80)

- Thermal property analyzer

- Humidity generator

Biomass pre-treatment

- Drying oven

- Thermal treatment

- Original acid cooking reactor with rheological measurement device at high temperature and saturated steam pressure

- Knife mills,

- Ball mill (Cryomill, Retsch)

Material manufacturing

- Thermopress

- Mixer

The Lignocellulosic track works in strong partnership with the Imaging platform and the Design & Instrumentation platform.