Downstream processes track

The Downstream processes track studies a set of unitary operations of clarification, concentration, extraction and purification with the aim of developing more economical, sober and sustainable processes for the valorisation of biobased compounds. The intensification of separative techniques and their optimal combination work to the competitiveness of biobased industries in terms of cost and reduction of environmental impact. The multi-scale scientific approach starts from upstream research to industrial application by mobilizing various skills such as transfer science, thermodynamics, chemical engineering and process engineering. The balance between experimental approaches and modeling allows to accelerate the scale-up steps of the developed processes. Modeling and predictive simulation also allow the identification of limiting factors and the numerical testing of technical solutions in order to remove obstacles for complex applications: separation of molecules that are very close in terms of structure or properties, non-equilibrium configurations in complex geometry, etc. This methodology is applied to various separative techniques in the solid-liquid, gas-liquid, gas-solid or immiscible liquid phases, with an emphasis on processes that are low in energy and chemical products, such as membrane or chromatographic processes. This allows the team to be present on a wide range of applications (food industry, industrial biotechnologies, green chemistry, environment, bioenergies ...).

Developed approaches

Extraction of compounds from recalcitrant biomasses

Some biological matrices present complex structures that are robust to the extraction of their intracellular compounds of interest. The team is interested in treatments upstream of the extraction process that can weaken or even destroy the cell walls, thus making the intracellular compounds more accessible. These treatments can be mechanical (ultrasound, centrifugation, grinding...), enzymatic or thermochemical.

These skills are applied to the valorization of microalgae, in partnership with the Biotransformation team. The destruction/fragilization of the cell walls of microalgae allows the extraction of many compounds with high added value (such as pigments, antioxidants, lipids, fatty acids, proteins).

Purification of compounds from plant or biotechnological origin

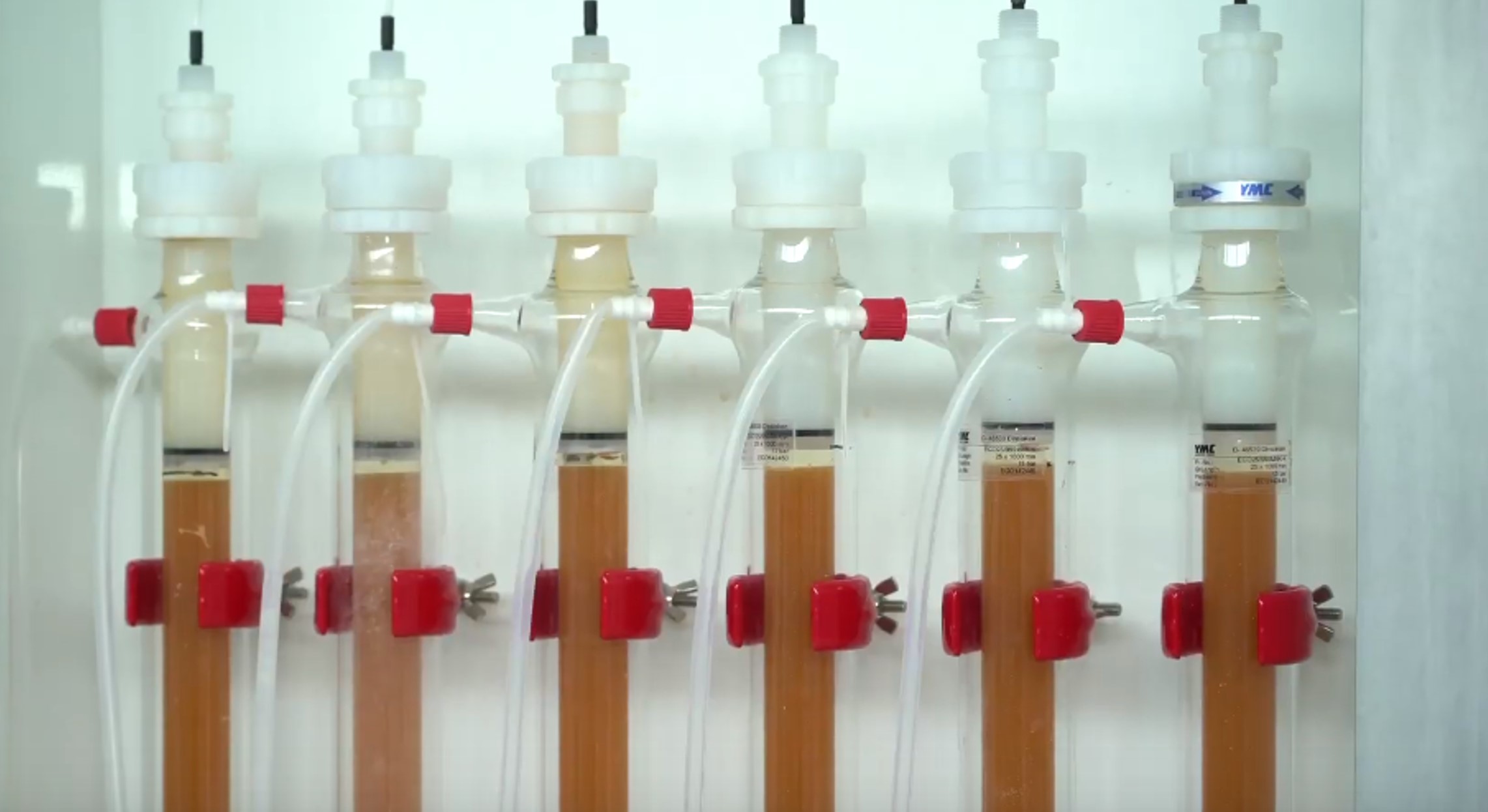

After extraction, biobased compounds are generally found in complex mixtures requiring separation and purification steps. The team is thus interested in the development and optimization of separative processes based on the coupling and intensification of various existing technologies such as membrane filtration, electrodialysis, preparative chromatography. The skills in modeling and predictive simulation of processes allow to quickly optimize the performance of existing technologies, and to develop improvements.

The processes developed are aimed at purifying compounds of interest from various families of plant or biotechnological origin, as well as valorizing co-products and effluents from the agri-food, wood or urban organic waste treatment industries.

Treatment of biobased gases

The Chair is also developing eco-efficient processes for the treatment of gases obtained from biomass (biogas, syngas) to allow a higher added value use. Indeed, the injection on the network or the uses as fuel (BioGNV, Hydrogen) require a high purity of these gases.

A strong expertise has been developed on the use of hollow fiber membrane contactors for the intensification of transfers during gas/liquid absorption washing processes. This technology allows to optimize the performances of classical washing processes. The modeling of the gas-liquid transfer at the interface according to the structure of the hollow fibers, allows to simulate the performances at a larger scale and to help the scale-up of the processes.

Examples of achievements

- Purification of organic acids obtained by fermentation or from biomasses by preparative chromatography

- Purification of pentoses from wheat straw or bran hydrolysate by combining ultrafiltration and conventional electrodialysis (patented process)

- Purification of polyphenols (resveratrol and its derivatives) from vine cell culture by adsorption

- Optimization of the demineralization of various products or co-products (fermentation musts, yeast extracts, protein molasses, hemicellulose hydrolysates, distillery vinasses) by ion exchange, membrane filtration or conventional electrodialysis

- Valorization of microalgae: harvesting, pre-treatment, extraction and purification of high added value molecules (lipids, pigments, anti-oxidants, proteins) and valorization of residues by methanization - Algues4Biomethane project

- Purification of agricultural biogas by G/L absorption with membrane contactor - EMMA Project

- Purification of syngas for hydrogen production - Vitrhydrogene Project

- Conversion of biogas or syngas into biomethane by biological methanation - Methagrid Project

Used technologies

The axis is based on the coupling of different technologies:

- Centrifugation

- Extrusion

- Ultrasound

- Membrane filtration (micro/ultra/nano filtration and reverse osmosis)

- Conventional and bipolar electrodialysis

- Preparative chromatography

- Gas/liquid membrane contactors

- Membrane Biomethanator

The equipment is mainly pilot equipment and is gathered in the Pilot Plant platform.