3D-Biomat Project

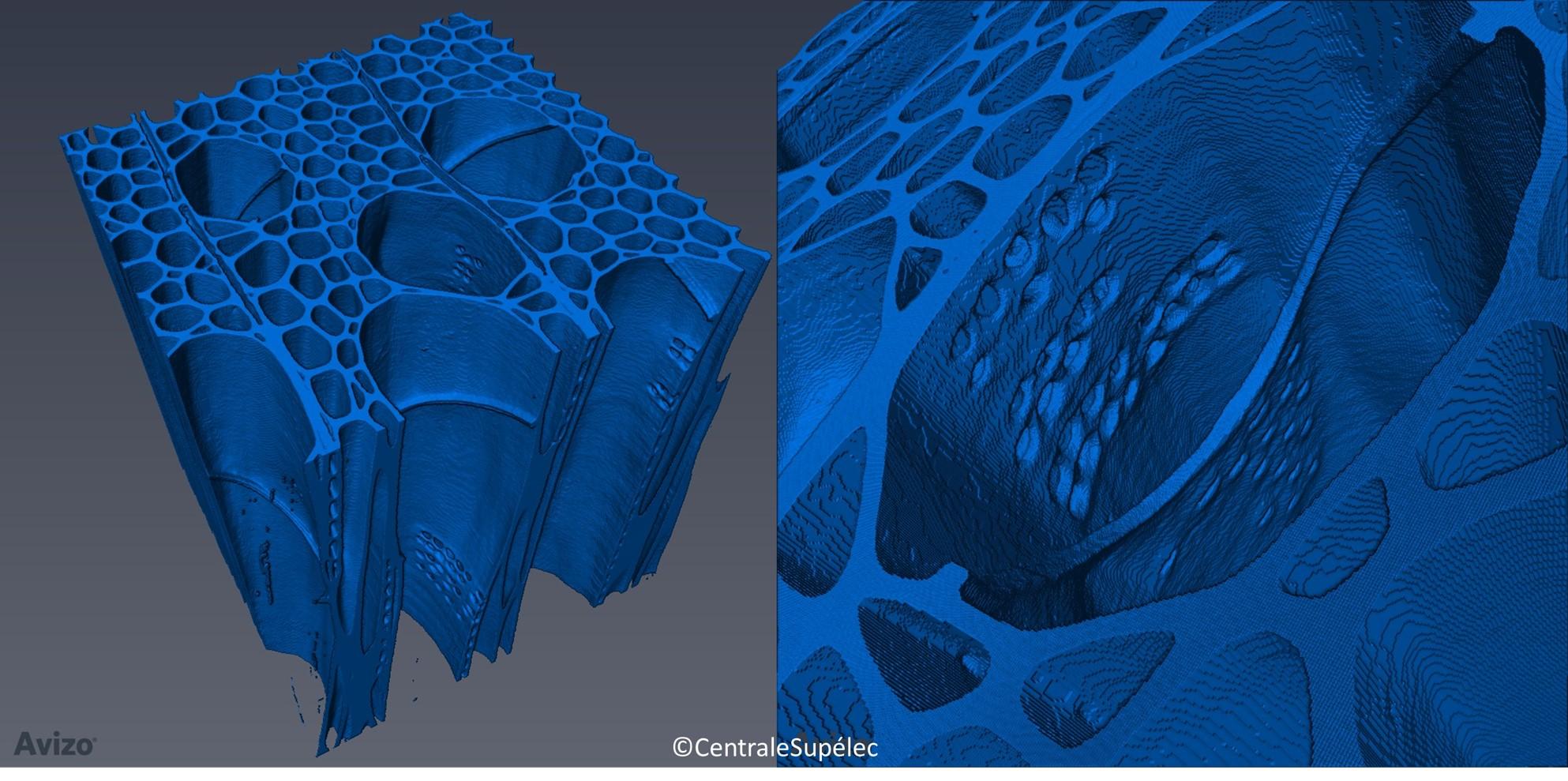

From nanometer to centimeter: experimental 3D investigation and multiscale modeling devoted to the innovation and development of plant fibers and biobased materials.

The 3D-BioMat project is at the heart of the axis Characterization and conversion of lignocellulosics of the chair of Biotechnology of CentraleSupélec. This project aims at assisting the design and manufacture of bio-based composites by visualization and simulation.

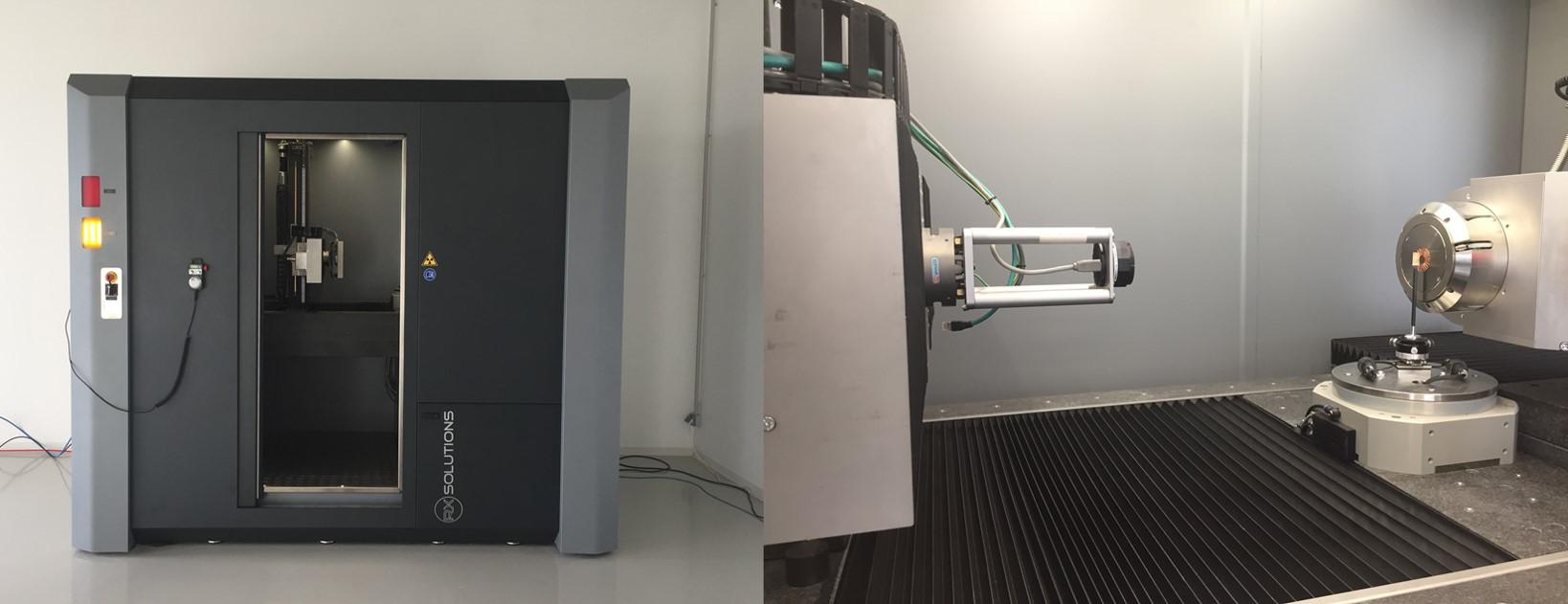

The main idea is to analyze the 3D morphology of fibrous materials and composites in order to better predict their behavior during the processes and during their life cycle. This is made possible thanks to the imaging-modeling coupling. The project is based on a 3D CT nano-tomograph from the latest generation (RX Solutions EasyTom XL Ultra 150-160) which is a flagship equipment with a sub-micrometric resolution (equivalent to synchrotron tomography lines). This resolution makes possible to observe the infra-cellular morphology and the details of the fiber-matrix interfaces which are key factors of the behavior of bio-based materials. Moreover, by decreasing the spatial resolution, fast scans can be obtained (in few minutes). The required source change between these two modes is automated, allowing a quick overview and then zooming at high resolution on the area of interest. This possibility is especially useful for diagnosis on problems arising from the industry.

This key equipment is at the core of the global and predictive approach in material sciences proposed in this project. By its ability to visualize in 3D with a high spatial resolution, it is suitable to characterize both the bio-resources and the morphology of the different phases of the materials after compounding. Numerical tools of upscalling in materials science allow to predict the properties of these materials by using these 3D descriptions. Those simulations are carried out in collaboration with the ROMEO High Performance Computing center since they need long computational time. Innovation in materials design requires an additional step, a reverse engineering approach in order to define the components and the best way of processing them to obtain materials with the desired performance (cost, development process, technical performance, etc.).

The ability of the tomograph to produce 4D images (3D observation as a function of time in response to mechanical loading or changes of temperature or relative humidity) allows to validate the predictive models and to test in situ materials from the industry.

Moreover, the use of a 3D printer (3D SYSTEMS® ProJet® 3500 HDMax) with a multijet modeling technology (MJM) allows the production of models of scanned morphologies for a research (observation of models behavior under loading) or pedagogical purpose. This 3D printer is co-financed by the Chair of Biotechnology of CentraleSupélec, the University of Reims Champagne-Ardenne and Grand Reims.

The synergy between the X-ray nano-tomograph, the additive manufacturing equipment and associated computational tools is dedicated to R&D, but is also useful in training to show advances in materials science (virtual navigation within materials, visualization of manufacturing defects or aging, observation of the behavior of a material during a tensile test, visualization of the migration of water, etc.).

To promote the creation of knowledge and to support the economic development of the region, 3D-BioMat relies on both the historical expertise of the Chair of Biotechnology and scientists hired within the framework of this project.

For a three-year period (from 01/05/2016 to 30/04/2019), the 3D-BioMat project is hosted by the Centre Européen de Biotechnologie et de Bioéconomie (CEBB 51110 Pomacle, France). With a total budget of 965,000€, 3D-BioMat is co-financed by the Grand Reims (31%) and the European Union by 48.7% (ie 50% of eligible expenditure). Europe is committed to the Grand Est with the European Regional Development Fund